Redefining Metal Additive Manufacturing

MOUND MUSEUM LECTURE SERIES SPOTLIGHTS

Summary

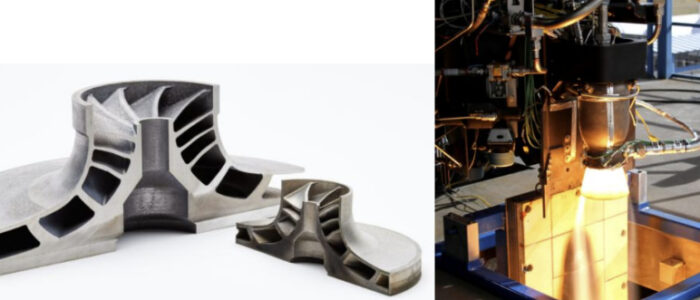

For decades, 3D printing has promised to revolutionize how we design and build things, but most systems have come with serious limitations, forcing engineers to simplify their ideas to fit what the machines could handle. Many of the leading companies in the field had been based in Europe and Asia, often focusing on incremental improvements to existing processes. Velo3D, a U.S.-based startup from Silicon Valley, set out to do something different. By rethinking the way metal 3D printing works, Velo3D developed technology that removes long-standing constraints and enables the production of complex shapes and fine details once thought impossible. This breakthrough is helping industries like aerospace and energy bring bold ideas to life, design lighter rockets, more efficient engines, and shorten innovation cycles. In this talk, I’ll share the story of Velo3D’s journey, how it stands apart from its global competitors.

Speaker’s Biography

Dr. Symeonidis has a BS in Metallurgy and a PhD in Aluminum casting. He graduated from W.P.I. and has worked in the field of metallurgy ever since. As an employee #6 and a driving force behind many of Velo3D’s breakthroughs Dr. Kimon Symeonidis is a named inventor on Velo3D’s patents. He has envisioned and delivered those formerly impossible overhangs, delicate walls, and complex internal paths that are now being realized in production. The company raised about $150M and became public with a value of $1.6B.

For additional details on this presentation call 937-353-4457. The presentation is free and open to the public and has ample free parking.

Mound Cold War Discovery Center

E-Mail: msem475@gmail.com

Phone: 937-247-0402

Web: www.daytonhistory.org

Comments are closed.